Contact: Bruce

Tel: +86-755-22 666 190

Fax: +86-755-29 043 136

E-mail: sales@ultrasonic-sensors.net

Skype: longsunac

Address: Room A1, 6/F, Bldg. No. 531, Bagua 3rd Road No. 277, Futian District, Shenzhen, China 518029

Double sheet sensors

1. Product Description

Double sheet sensor mainly used to monitor multilayer paper, plastic and metal film. In order to identify two or more than two sheets accidentally stuck together. Detection value for each layer will be compared with the stored reference one and accordingly is indicated as single or double, moreover it can be manually corrected stored value. Mainly for single sheet detection, double sheets alarm function, and is not limited by detected object due to vibration, material, color, and is widely used in papermaking, stamping, instant noodles packing machine and other industries. Double sheet sensor which uses specially developed ultrasonic transducer and originality of electronic circuits can be widely applied to material thickness detection, transparent materials and thin metal films etc double sheets overlapping accurately detecting. The ultrasound system is superior to a photoelectric double sheet detector because it does not depend on the color of the material. Compared to traditional mechanical or optical detector, double sheet ultrasonic sensor does not need to set up, which can accommodate a variety of sheet material.

2. Features

Contains a signal processor and two ultrasonic sensors (transmitter and receiver);

Reliable detection: one or two more sheets of paper, plastic or metal foil, the sensing range: 20-60mm;

Measuring range of materials from paper 20g/m2 to 400g/m2 card;

Measurement speed: 1 time/20ms;

Installation dimensions: thread M18*1.5;

Resolution: three kinds of signals output (air, single sheet, two or more sheets), applications can be a various.

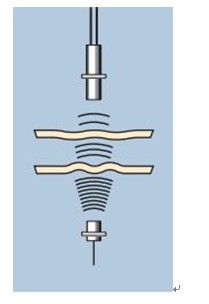

3. Product principle

A high frequency ultrasonic transmitter is emitting a bundle of ultrasonic waves below the sheet. The sheet vibration caused by sound waves, which also will be in the other side of the sheet, in turn, produces a very small wave. The small sound waves are received by ultrasonic receiver. If two sheets, one on top another, the signal becomes weaker, so basically can not reach the ultrasonic receiver.

4. Main specifications:

Supply voltage: DC 24V ± 15%

Working temperature: probe -20 ~ 70 ℃

meter -20 ~ 60 ℃

Storage temperature: -40 ~ 80 ℃

Working range: 20g/m2 to 400g/m2 paper cards

Electrical Interface:

Blue: PNP + White: PNP- Green: NPN +

yellow: NPN- Red: 24VDC + Black: 24VDC-

Analog Display:

Green: out of paper (PNP, NPN output high)

Yellow: one sheet (PNP output signal, normally open) (PNP output Low, NPN output is high)

Red: two or more sheets (NPN output signal, normally open) (NPN Output is low, PNP output is high)

LED Display: Displays the paper states 0,1,2

Housing Material:

Electronic Processor: metal

Sensor: plastic (anticorrosion, please use special materials)

5. Installation

![]()

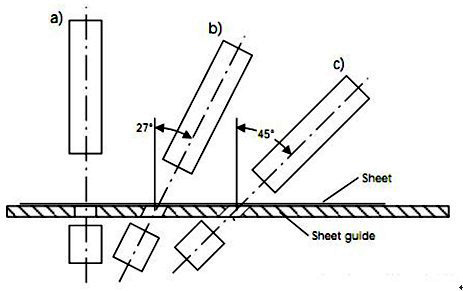

Double sheet sensors can be installed perpendicular to the paper, in the detection of ordinary paper and film, paper swing will not affect the functionality of the system.

For thin sheet metal and thicker plastic film (example: credit card), the proposed system is tilted 27 ° installation testing.

For a special type of paper is thicker, the system should be tilted 27 ° ~ 30 ° installation.

6. Wiring

Blue: PNP + White: PNP-

Green: NPN + yellow: NPN-

Red: 24VDC + Black: 24VDC-

Note: The controller enclosure please grounded! ! !

7. Precautions

A. The controller enclosure reliably grounded!

B. The distance between the transmitter and the receiver must be at least 20mm, up to 60mm. Precise axial alignment (± 1 °) is very important. If the transmitter and receiver axis Not aligned, then the performance will be reduced.

C. Recommended installation distance: 28mm (± 1mm).

D. Recommended installation angle: 27 ° ± 1 °.

E. Before power on, ensure that the output signal (blue, white, green, yellow) cables are not shorted.

F. Calibration: When the paper falsely detected, for example, single sheet detected as double ones or double sheets as a single sheet, please operate according to the following steps:

1) Put a piece of paper between the ultrasonic emitter and receiver, press the right button, until the three lights flashing, release the right button;

2) The two pieces of paper placed between the ultrasonic emitter and receiver, press the left button until the three lights flashing, release the left button;

G, Reset: If the product appears abnormal status, you can try to press two buttons simultaneously, until the three lights flashing, release both keys at the same time, this is a product reset.